Are Tesla quality and production issues due to robots? (Update)

|

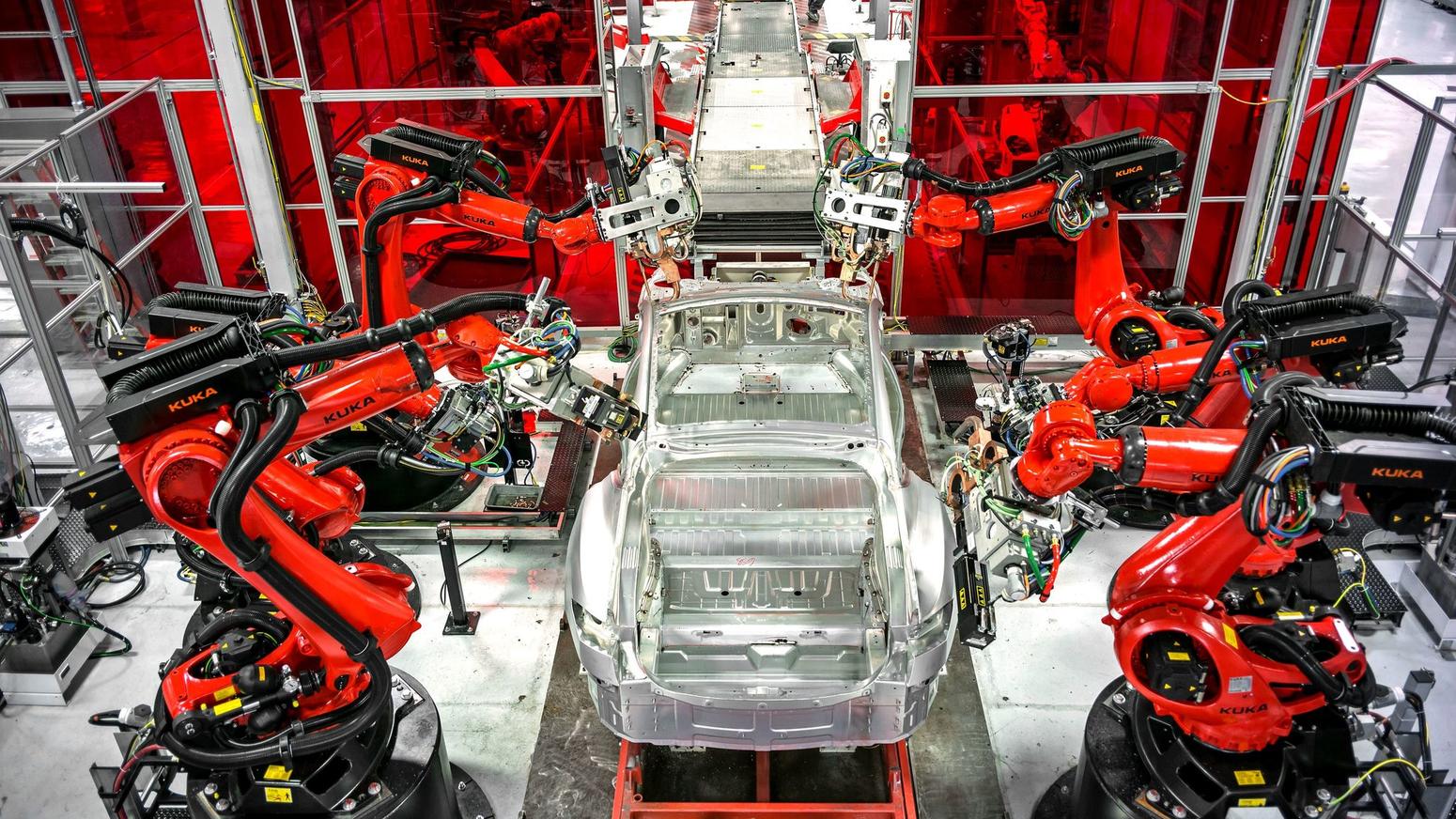

| Tesla prides itself in putting Americans out of a job with its expensive Kuba robots, and now it is biting them in the posterior |

UPDATE This rumor from last November is upgraded to 'fact' today. In a rare win for humans over robots in the battle for labor efficiency, Wall Street analysts have laid down a compelling argument that over-automation is to blame for problems at the billionaire Elon Musk's electric-car company.

That is to say, the very innovation and competitive advantage that Musk says he's bringing to the car industry – his nearly fully automated plant in Fremont, California – is the reason Tesla is unable to scale quickly.

According to the Bernstein analysts Max Warburton and Toni Sacconaghi, it's the robots that can't pump out Tesla's highly anticipated Model 3s fast enough.

The whole process is too ambitious, risky, and complicated.

From Bernstein: "Tesla has tried to hyper-automate final assembly. We believe Tesla has been too ambitious with automation on the Model 3 line. Few have seen it (the plant is off-limits at present), but we know this: Tesla has spent c.2x what a traditional OEM spends per unit on capacity.

Elon Musk told investors that factory model assembly was the biggest constraint on Model 3 production.

"It has ordered huge numbers of Kuka robots. It has not only automated stamping, paint and welding (as most other OEMs do) – it has also tried to automate final assembly (putting parts into the car). It talks of two-level final lines with robots automating parts sequencing. This is where Tesla seems to be facing problems (as well as in welding & battery pack assembly)."

Warburton, who spent his career before Wall Street at the International Motor Vehicle Program – a partly academic, partly commercial organisation based at MIT – wrote that "automation in final assembly doesn't work".

Bernstein adds that the world's best carmakers, the Japanese, try to limit automation because it "is expensive and is statistically inversely correlated to quality". Their approach is to get the process right first, then bring in the robots – the opposite of Musk's.

|

| Liberal buddies Obama and Musk in 2015. Musk received an estimated $4.9 billion in Obama government subsidies for Tesla and he turns around and buys robots instead of hiring Americans. And Tesla is burning through $8,000 per minute with those shiny robots, robots with no human intelligence to make split second decisions to adjust so cars coming off the line have less flaws |

11/30/17 Maybe humans can't be replaced by robots after all. At least not yet.

Tesla prides itself on its automated assembly lines, but fact is the production lines staffed by humans at other manufacturers are making those Tesla robots look pretty inferior.

——

More than 90 percent of Tesla Model S and X EVs have defects when they come off the assembly line, according to a Reuters report. The agency talked to nine current and former employees, including a former senior manager “with experience in assembly, quality control and repairs on the Model S and Model X." For comparison, brands like Toyota require fixes on fewer than 10 percent of cars. Tesla, for its part, says its quality control process is more rigorous and that most fixes only take a few minutes.

At Tesla, "so much goes into rework after the car is done … that's where their money is being spent," a former Tesla supervisor said. All sources spoke under the condition of anonymity, due to non-disclosure agreements. Bigger fixes, workers told Reuters, go to a lot called the “yard," which has exceeded 2,000 vehicles at times. Tesla denied to Reuters that such lots exist.

Defects included "doors not closing, material trim, missing parts, all kinds of stuff. Loose objects, water leaks, you name it," another former supervisor told Reuters. "We've been building a Model S since 2012. How do we still have water leaks?"

Some of the problems, workers said, came from pressure to keep the assembly lines moving. Batches of cars sometimes are sent through with parts missing.

"Our goal is to produce perfect cars for every customer," Tesla said in a statement. "Therefore, we review every vehicle for even the smallest refinement. Most customers would never notice the work that is done post production, but we care about even a fraction of a millimeter body gap difference or a slight paint gloss texture. We then feed these improvements back to production in a pursuit of perfection."

The Silicon Valley company has been in the news constantly over the last few months, both for problems and for new products like the Tesla semi truck and new Roadster. Bloomberg reported last week that the company is burning through about $1 billion in cash per quarter, which comes out to $8,000 per minute. Model 3 production delays are a big part of that cash burn. Earlier this summer, Tesla forecast it would produce 5,000 Model 3s per week by the end of the year and then work to double that to 10,000 cars per week by the end of 2018. That has now been pushed back, with Tesla hoping to hit 5,000 cars per week by next March. Jake Lingeman/AutoWeek