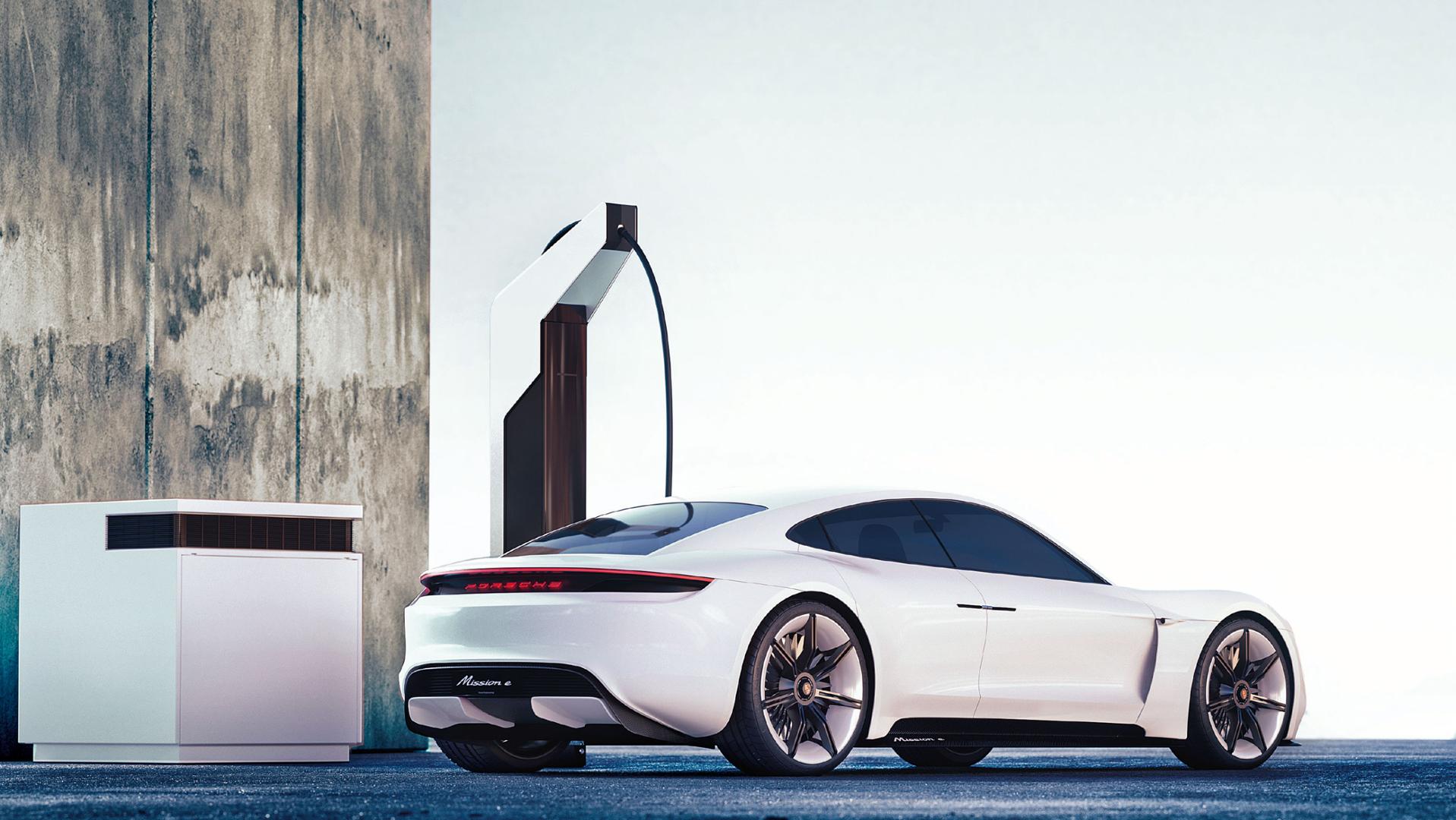

Electric pit stop

|

| Porsche Taycan using 800V Porsche charger |

For every purpose, be it in the parking garage, at the supermarket or freeway rest stop, Porsche Engineering has developed a fast-charging solution: a system with modular building blocks that takes account of the available electricity grid, visitor frequency and space constraints.

For the first time, economic viability and user-friendly design are brought together in a charging solution that will help electromobility gain greater acceptance.

Looking at the fast-charging stations in use today, the disadvantages of the system are readily apparent at a glance. At present, all of the components needed for charging are installed in every single cabinet: transformer, galvanic isolation, power electronics, cooling and connectivity—significant outlays that make each individual charging station disproportionately expensive. So for Porsche Engineering, a charging park with a new system architecture and a new generation of charging stations quickly crystallized as an alternative. This new generation of devices is characterized by impressive fast-charging technology. It provides an attractive interface to the customer and, thanks to low operating costs, also presents a compelling business case for a wide variety of operators. The innovative charging park system designed by Porsche Engineering also provides the capability to charge the batteries of multiple electric cars at the same time. Thanks to 800- volt technology, batteries can store enough energy for roughly 400 kilometers of range in just 20 minutes. Enough time for a coffee break at the rest stop or a few errands in the supermarket or shopping area.

FlexBoxes—building blocks of the architecture

[adinserter name="GOOGLE AD"]The charging park system from Porsche Engineering is designed as a modular system comprised of standardized, weather-proof housings, the FlexBoxes (exterior dimensions: 120 x 120 x 130 centimeters). They enable flexible outfitting with all necessary components in a standard rack and can be positioned at quite some distance from the charging stations, for example behind a building or hedge. So both visually and in terms of noise, they are hidden from the customer. There are also ideal integration options for planned and existing buildings: The modules can be positioned wherever there is space, while the slim and user-friendly charging poles are optimally positioned for use by customers

So in terms of space, there are no general prerequisites for setting up a charging park system according to the Porsche Engineering principle. One technical advantage for medium-sized to large charging parks is that a connection to the medium- voltage grid (up to 36 kilovolts of alternating current) exists. A transformer then converts this medium voltage into low voltage (local grid level). On the secondary side of the transformer, the same lower AC supply is always available irrespective of the location.

The intelligent design of the transformer also enables the accommodation of the galvanic isolation necessary for safety purposes. The benefit is clear: The centralized galvanic isolation obviates the need for it in each individual pole. Until now, it has been a part of the power electronics in all such poles, taking up space and driving up costs. Even for locations where this prerequisite is not in place, there is a transformer box solution available. This solution retains the major benefits of an optimal package and aesthetic design.

Greater efficiency—lower operating costs

In addition to the lower system costs, the lower operating costs are also a substantial factor, for the Porsche Engineering charging park also functions more intelligently. The control server of the transformer station brings together all of the information from all control units of the hardware—comparable to a local network. This central brain checks and connects the control units for the cooling unit, the power electronics and the charging station. The control server also handles the communication with the back-end of the respective operator for settlement purposes. The result: Thanks to this innovative architecture, efficiency is boosted to over 95 % for the complete system, which means the possibility of significantly lower operating costs compared to systems available today.

PowerBox

|

| The concept of the charging park from Porsche Engineering enables cars to charge up in just 20 min. |

First, the low-voltage alternating current from the transformer station is converted into direct current in the PowerBox. The PowerBox can be equipped with two sets of power electronics and supply two charging points. The system utilizes silicon carbide (SiC) modules of the latest generation. The advantages compared to modules based on currently available technology consist in lower conduction, switching losses and space requirements.

Moreover, elements such as line filters can be built more compactly due to the higher pulse frequency. The components are designed to accommodate a distance of up to 200 meters between the transformer station and PowerBox and up to 100 meters between the PowerBox and the charging station. All in all, this results in the high flexibility required to position the components at any given location. Technically speaking, even greater distances would be possible, albeit with higher power losses and, above all, higher construction costs.

CoolingBox

Another important component of the charging park is the CoolingBox. The CoolingBox provides liquid cooling for the charging poles and power electronics. Every CoolingBox can accommodate two cooling units, each of which provides reliable cooling for multiple charging points under all operating conditions. On the exterior, a CoolingBox differs from the other FlexBoxes of the charging park system with its ventilation fins for intake and exhaust air. The CoolingBox is optimally positioned at some distance from the charging stations. This ensures that the unavoidable noises associated with cooling are kept far from customers’ ears.

ComboBox—the alternative for small charging parks

The Porsche Engineering development can also respond flexibly to the special requirements of charging park operators such as extremely limited space— for example at smaller locations. If the operator works with just a few charging points, a compact alternative system is offered: The ComboBox combines the PowerBox and the CoolingBox— a power unit with a cooling unit sufficient for one charging point each.

ChargeBox—fast charging even without medium voltage

Even for cases in which no sufficiently powerful grid connection is available, the modular charging system offers a solution with which electric cars can be charged extremely fast. Specially designed for this purpose, the ChargeBox contains an additional buffer storage battery in addition to a power unit. This buffer battery is charged while no vehicle is using the charging station. Thanks to the storage battery as a replacement for grid power, the customer has access to high charging capacity at locations without medium-voltage grid connection as well. The ChargeBox is ideal for locations with a low charging frequency per day and in situations in which an expansion of grid capacity would be expensive. The ChargeBox is available as an entry-level model with a 70 kWh battery and a 160 kW charging station.

For more highly frequented locations, for vehicles with higher charging capacities or as a subsequent retrofit, there is also a fully equipped version with 140 kWh and two 160 kW charging stations, combinable for 320 kW. Another important element of the solution is provided by the smart grid unit at the grid connection point, which ensures that the system never draws more than the permissible amount of electricity from the grid. This component also helps with the use of electricity from an existing PV system for fast charging and supports consumption optimization efforts through energy recovery mode at the location.

Premium charging stations

The end customer notices nothing of the underlying technology. The same point of contact is always there: The charging stations are the single customer touchpoint with the driver of an electric car. Porsche Engineering designed the charging stations with the highest standards in terms of design and ergonomics for a positive charging experience while focusing in equal measure on the highest functionality and economy. As the engineers removed everything from the charging station that wasn’t absolutely required at the customer touchpoint and packed it into FlexBoxes, a streamlined appearance could be achieved—and thus a typical Porsche design identity. That was, after all, an integral part of the design specs, aside from the universal applicability in all parking space situations. The crane-like shape of the poles is no coincidence: The high-positioned, liquid-cooled charging cable reaches the charging socket of every electric vehicle. After all, the idea is for electric vehicles from all manufacturers to be able to charge up here. A large, 10-inch touch display offers a wide variety of options for interacting with the customer. Altogether, this meticulously devised concept is intended to ensure that the customer’s experience of the charging process is uncomplicated and pleasant.

The aesthetic impulse also finds expression in multiple lighting elements: A visible stripe on the front of the charging station displays the operating mode. Light units to the left and right subtly mark the borders of the charging station and define the area of the parking space.

The right juice for every electric model

As flexible as the Porsche Engineering development is in terms of the individual structure of the charging park, it is every bit as flexible with regard to the charging convenience offered to the customer. The charge control unit in the station automatically establishes the communication with the vehicle. It instantaneously compares the requirements of the vehicle with the capabilities of the charging station at the beginning of the charging procedure. If a vehicle is set up for the 800-volt technology developed by Porsche, it can be charged at high power. But the charging station from Porsche Engineering also supplies vehicles designed for lower charging power levels. They, too, receive the electricity they need

Technologically, Porsche employs the Combined Charging System (CCS1/CCS2) as the European standard. This is adapted to the higher voltage level and higher currents of the charging park. With minor modifications to the charge control unit, however, it is also possible to implement charging standards such as CHAdeMO or GB/T, enabling service to other vehicles even in regions as far afield as Japan and China.

Reliable—now and in the future

In addition to the high degree of flexibility offered to operators and customers today, great attention was also given to ensuring the system would be able to keep up with future developments as well. For that reason, Porsche Engineering colleagues from Prague developed the software for the control of the charging park, the charging procedure and the server connection themselves. This not only makes the charging park smart-grid-capable—i.e. able to actively communicate with the infrastructure— but also makes it possible, thanks to the integrated, centralized intelligence, to continue operating even if, for example, the back-end communication to the operator’s electronic payment system goes down. The charging point remains available to the customer even in such situations. Porsche Engineering set out with the objective of ensuring safe, convenient and fast charging in every situation. Thanks to this unwavering focus on the customer, and the intelligent design, the new charging infrastructure from Porsche Engineering provides the optimal solution for practically every operator.