AI-Powered Diagnostics: The New Frontier in Auto & Race Car Maintenance

AI-Powered Artificial Intelligence) has significantly improved the way things are done in the realm of automobile and race car maintenance.

In place of traditional maintenance models like preventive and reactive maintenance, AI-powered diagnostics enable predictive maintenance — vastly improving auto repair efficiency and maintaining vehicle longevity.

Whereas reactive maintenance means waiting for something to break before fixing it, preventive maintenance relies on scheduled repairs and replacement of parts, whether or not they’re broken. Both are traditional methods that fall short, especially when it comes to performance cars in the racing world, where precision and timing are everything. Replacing expensive parts much earlier than needed may also tack on additional and unnecessary costs.

Predictive maintenance, on the other hand, uses AI to prevent issues before they become a problem. This is done by taking several data points into account, such as car temperature, RPMs, gas, location, and other measurable metrics.

Key Benefits of AI in Race Car Repair and Maintenance

AI-Powered diagnostics offer several key advantages tailored specifically for automotive racing:

- Cost Efficiency: By employing AI-based predictive maintenance strategies, racing teams can avoid costly major repairs while ensuring parts are only replaced when truly necessary, optimizing their budget.

- Improved Vehicle Performance: AI assists crew members and drivers in identifying potential problems before they escalate. This proactive approach ensures that vehicles operate smoothly and efficiently, ultimately enhancing performance on the track.

- Enhanced Safety: AI systems analyze data from vehicle sensors, enabling rapid identification of safety risks. By predicting issues, teams can take immediate action, significantly enhancing driver safety during races.

- Fewer Breakdowns: With AI-driven predictive maintenance, teams experience fewer unexpected breakdowns. Repairs and maintenance can be scheduled at optimal times, reducing the likelihood of issues during critical racing moments.

How AI-Driven Predictive Maintenance Works

One effective model used in AI-Powered diagnostics is the Guided Repair Model. This approach employs AI to drive predictive maintenance strategies and provides detailed instructions to help mechanics and team managers make proactive maintenance decisions.

The Guided Repair Model analyzes vast amounts of data, including vehicle wiring diagrams, sensor data, historical maintenance records, telemetry data, and environmental conditions to create forecasts that predict when and where vehicle parts might fail. By integrating real-time performance metrics, such as engine temperature, RPMs, and tire pressure, the model can generate accurate insights into vehicle health.

Predictive-diagnostic-based alerts allow for reduced downtime, which facilitates the maintenance of high-performance vehicles to be scheduled during less busy hours. They also improve driver safety on the road through their ability to anticipate possible engine and part failures even before they cause an issue or endanger the driver.

By regularly addressing potential issues, vehicles are kept in tip-top shape and are able to perform optimally for longer. Predictive maintenance thus allows automotive racing car owners and mechanics to shift from reactive maintenance to strategic maintenance, giving them more control over their vehicles and costs.

What is an Automotive Digital Twin?

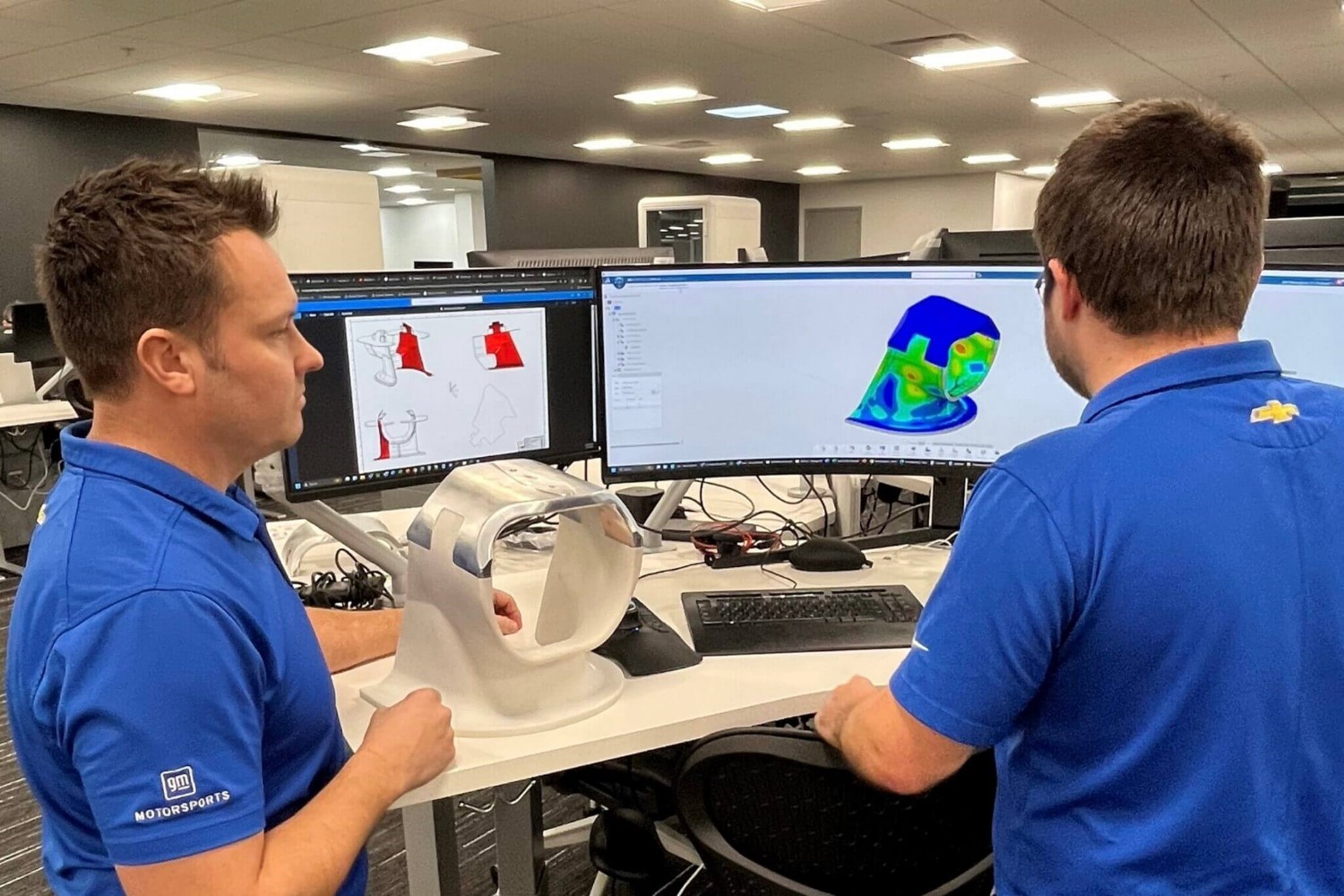

Digital twin technology allows manufacturers and mechanics in the automotive industry to generate a virtual replica, a “digital twin” of an actual vehicle, down to its parts for real-time monitoring, assessment, and simulation.

Prominent companies like Tesla, BMW, Ford, and GM already use this technology in applications such as:

- Creating virtual prototypes to test and refine parts during early-stage designing

- Simulating and optimizing vehicle performance under various conditions

- Simulating crash tests to help manufacturers meet safety standards

- Optimizing production procedures, including tooling design and assembly line layouts

- Monitoring car health on an individual level, down to weather reports, GPS, and sensors — thereby predicting component failures and optimizing maintenance schedules

Expanding the Reach of AI-Powered Diagnostics Beyond Racing

Needless to say, the benefits of AI-Powered diagnostics go beyond automotive racing. For fleet managers, the advent of AI-powered diagnostics can lead to reduced fleet management costs. AI diagnostics can spell a difference for small businesses like mechanic shops as well, helping them to accurately pinpoint car problems and eliminate guesswork. This not only provides cost savings for consumers but also eases the burden for those in charge of assessments and labor.

From a manufacturing perspective, AI also allows manufacturers to make well-informed decisions and helps them identify faulty parts before they cause issues, ultimately improving overall car quality and safety. Additionally, AI diagnostics data can inform future design and engineering decisions, ultimately leading to improved vehicle reliability and performance. Overall, the shift towards AI-based maintenance drives industry progress and encourages a culture of better driver safety and fuel efficiency.