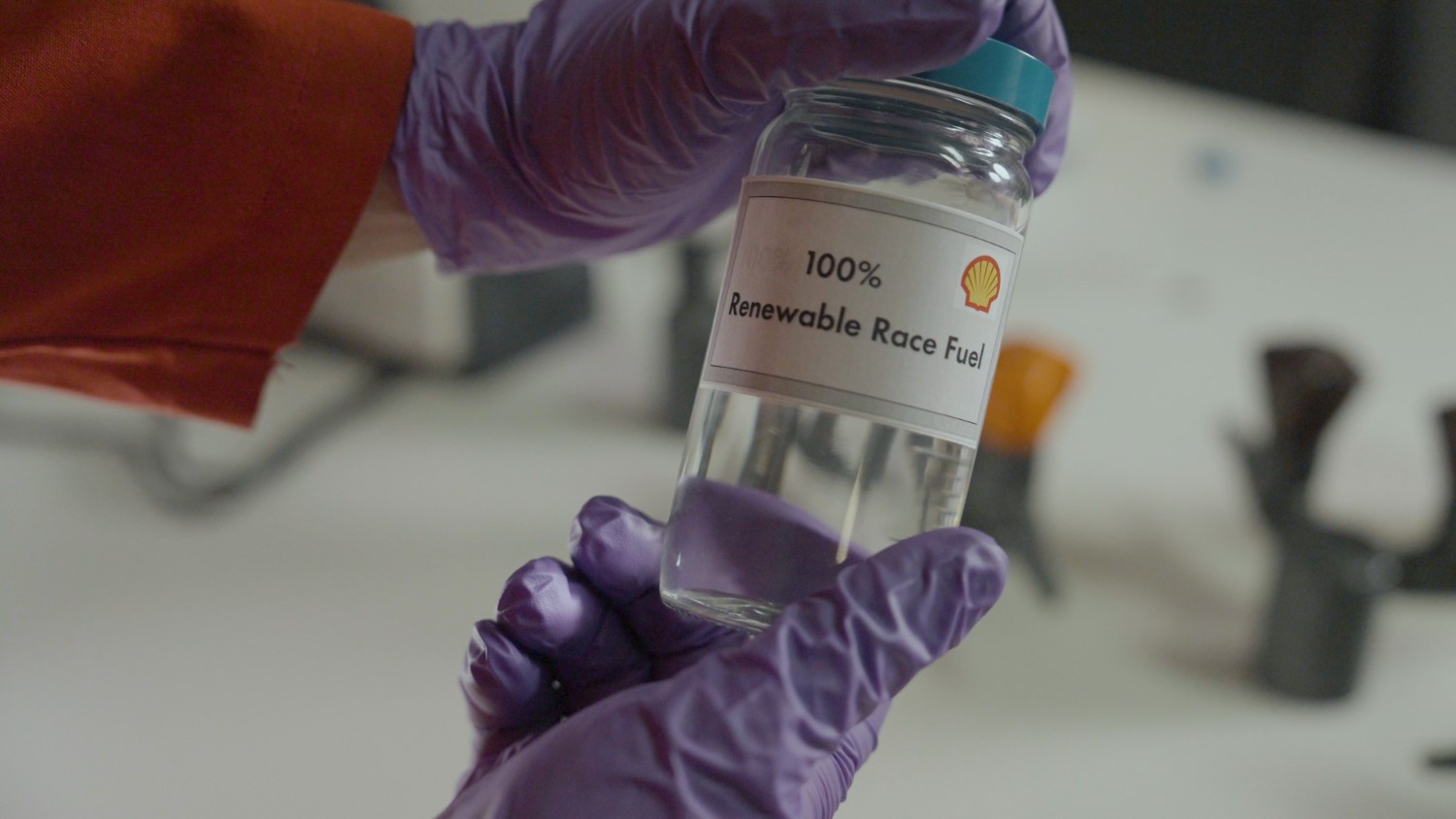

IndyCar: Shell to provide IndyCar with 100% renewable race fuel

The NTT INDYCAR SERIES ushered in a new era of sustainability in the open test Feb. 2-3 at The Thermal Club with the eagerly anticipated arrival of Shell 100% Renewable Race Fuel, advanced technology that will power the series’ race engines beginning with the 2023 season.

With the debut of the new fuel developed by Shell, the NTT INDYCAR SERIES becomes the first United States-based motorsports series to power racing with 100% renewable race fuel that enables at least 60% greenhouse gas emissions reduction compared to fossil-based gasoline.

The second-generation ethanol, derived from the waste portion of sugarcane, is sourced from Brazil. The product is part of a joint venture between Shell and Cosan, with Raízen, Brazil’s second-largest fuel distribution company, playing a critical role as the leading manufacturer of sugarcane ethanol in the country and the largest individual sugar exporter in the world.

“Shell’s 100% Renewable Race Fuel powering all competing vehicles in the INDYCAR SERIES in 2023 contains a significant mix of second-generation ethanol combined with another renewable component to create the 100% renewable formulation that will reduce the greenhouse gas emissions by at least 60 percent compared to fossil-based gasoline,” said Bassem Kheireddin, Shell technology manager of motorsports. “We are very proud to bring it to the series, and it’s a step to decarbonize motorsport.”

A process that took a little over a year to develop came as part of the recently announced extension of a multiyear agreement between Shell and the Penske Corporation. Penske Entertainment, a subsidiary of Penske Corporation, owns INDYCAR and the Indianapolis Motor Speedway.

Working together with INDYCAR engine suppliers Chevrolet and Honda, the Shell 100% Renewable Race Fuel can meet the demands of a race weekend without any changes in performance.

For Kheireddin, watching 27 drivers be powered by the new sustainable fuel take to the 3.067-mile, 17-turn natural terrain road course just outside Coachella Valley in Thermal, California, was a proud moment. There were a total of 7,851.52 miles (2,560 laps) logged during the two days of testing.

“This test was very important to see for the first time in action on the racetrack,” he said. “Shell uses motorsports as a proving ground for pushing the boundaries of fuels technology, and this 100% Renewable Race Fuel is now in action. We’re not seeing anything different from the racing perspective, and neither will fans.”

While the Shell 100% Renewable Race Fuel is a massive step forward in both sustainability and technology, the plan for Shell is to continue to press forward and be one step ahead of an ever-changing world.

“It’s in Shell’s DNA to innovate, and we believe the racetrack is a proving ground from the high speeds, the high temperatures, the extreme conditions,” Kheireddin said. “And then we take those learnings to transfer them to our road-going products. Now, as far as what’s next for this particular fuel, that will depend on what the INDYCAR SERIES plans for the future. We will continue to innovate and work hand in hand with the engine manufacturers with whatever sustainability initiatives come along the way.

“We at Shell are very excited to see how this journey unfolded from taking fuel innovation from the lab to the dyno test to the track.”

The 2023 season starts March 3-5 with the Firestone Grand Prix of St. Petersburg presented by RP Funding on the streets of St. Petersburg, Florida. Live coverage of the race will be available at noon ET Sunday, March 5 on NBC, Peacock, Telemundo Deportes on Universo and the INDYCAR Radio Network.

Tested and ready for action

Twenty-seven racecars powered by the new sustainable race fuel recently tested on a natural-terrain road course in Thermal, California, to prepare for the rigors of the 17-race season.

The on-track sessions followed multiple months of testing on dynos at GM’s Performance and Racing Propulsion facility and Honda Performance Development. The high-octane fuel can meet the demanding needs of Chevrolet’s and Honda’s 2.2-liter, twin-turbocharged V6 engines and INDYCAR fans should not expect to see any performance changes with the utilization of the new 100% renewable race fuel from Shell.

The engine manufacturers (Honda and Chevrolet) with the INDYCAR Series executed both performance and durability tests and Shell has received approval from both manufacturers.

“It’s a huge step for the series from a sustainability standpoint. Not easy to do and Shell has made that happen,” said two-time INDYCAR champion Josef Newgarden. “I thought the performance on the 100% renewable fuel was fantastic.”

International joint venture for sustainability

Shell’s innovative formula of second-generation ethanol, derived from the waste portion of sugarcane combined with renewable components obtained from non-food waste (supplied by a third party), is part of a joint venture between Shell and Cosan, with Raizen – Brazil’s leading manufacturer of sugarcane ethanol and the largest individual sugar exporter in the world – playing an important role in the supply process.

The second-generation fuel is produced from non-food waste.

“This is great for us because we don’t compete with the food chain,” said Dr. Selda Gunsel, Vice President, Fuels & Lubricants Technology at Shell. “We replaced the remaining component, the fossil-based gasoline, with a renewable component. There are absolutely no fossil-based molecules from a chemical engineering perspective in this formulation.”

Numbers to note

100 octane rating of Shell race fuel

1st U.S.-based motorsports series to run on 100% renewable race fuel

60% reduction in greenhouse gas emissions compared to fossil-based gasoline*

18.5 U.S. gallons in an NTT INDYCAR SERIES fuel cell

2007 was when INDYCAR started using fuel-grade ethanol instead of petroleum-based methanol

2012 was when INDYCAR switched to an 85% fuel-grade ethanol blend

2 NTT INDYCAR SERIES long-time engine suppliers — Chevrolet and Honda

3.25 billion liters of sugarcane cellulosic ethanol Shell has purchased under a long-term agreement with Raízen

17 races in the 2023 NTT INDYCAR SERIES, starting with the 19th race in series history in St. Petersburg, Florida

27 drivers entered in the race who will use the 100% renewable race fuel

28th season under INDYCAR sanction, featuring the 107th Indianapolis 500

2050 is the target for Shell to become a net-zero emissions company**

*Reduction in lifecycle greenhouse gas emissions relative to 2005 baseline average gasoline as defined in the RFS. Estimations for Shell Fuel based on CA-GREET model values provided by supplier and published fuel pathways in the California Low Carbon Fuel Standard (LCFS).

**To reach this net-zero emissions target, our business plans will have to change as our customers’ needs evolve – current plans alone won’t get us there. There is significant risk that we won’t reach this target if society isn’t at NZE in 2050.

What they’re saying

“We should be shouting that from mountaintops. It’s very cool what Shell has been able to provide us, and I think the Chevrolet engine has adapted quite well to it.”

— two-time INDYCAR champion Josef Newgarden

“We’re glad that Shell has been able to bring the renewable race fuel into INDYCAR now, so we are ready to go and help the planet.”

— four-time Indianapolis 500 champion Helio Castroneves

“Penske Corporation is a global industry leader like Shell, and we are focusing on sustainability and decarbonization with the ultimate goal of zero carbon emissions.”

— Roger Penske, Penske Corp. Chairman

“With industry leading organizations like Shell and Penske sharing the same ambition for a cleaner energy future, remarkable progress can be made.”

— Mark Miles, President & CEO of Penske Entertainment Corp.

“The fuel and lubricant, and energy solutions developed through our strategic relationship with INDYCAR and Penske Corporation can ultimately help accelerate reduced carbon emissions from transport in many sectors of the economy.”

— Carlos Maurer, Executive Vice President of Sectors and Decarbonization, Shell

“Global demand for sustainable fuels is growing. Combining Raízen’s innovative sugarcane waste technology with Shell’s global distribution network and customer relationships will help to meet that demand.”

— Andrew Smith, Executive Vice President for Trading and Supply, Shell

“We will continue to innovate and work hand in hand with the engine manufacturers with whatever sustainability initiatives come along the way. We at Shell are very excited to see how this journey unfolded from taking fuel innovation from the lab to the dyno test to the track.”

— Bassem Kheireddin, Technology Manager of Motorsports, Shell