Tesla lowers production costs significantly

|

| The next Tesla, the Model S, will sell for just $49K when it goes on sale in late 2011 |

The CEO of Tesla Motors said Monday that the material cost of the electric car company's Roadster sports car has dropped to about $80,000 (U.S.), which should help the company reach profitability next month.

Elon Musk said in a blog post on Tesla's website that the material cost, which is the total cost of the parts and components that make up each vehicle, was as high as $140,000 in the summer of 2007.

The car currently has a starting sticker price of $109,000.

"Combined with a steady production volume of 20 to 30 per week in the third quarter this year and a good take up rate of the higher priced Roadster Sport, we expect to cross over into profitability next month," Musk wrote in his blog post.

The Roadster, a two-seat electric sports car, can get more than 321 km on a single charge with an acceleration of 0-to-96 km/h in just under 4 seconds.

Musk said a key step toward lowering the costs was moving production of the vehicle's battery packs from a factory in Asia to the San Carlos, Calif.-based company's home state.

"This may sound counterintuitive, but our unit cost actually went down and quality improved as we went to a more automated system and could iterate quickly with engineering to find design efficiencies, " Musk said.

In addition, moving production of the heavy and bulky battery packs significantly lowered the company's shipping costs, he said.

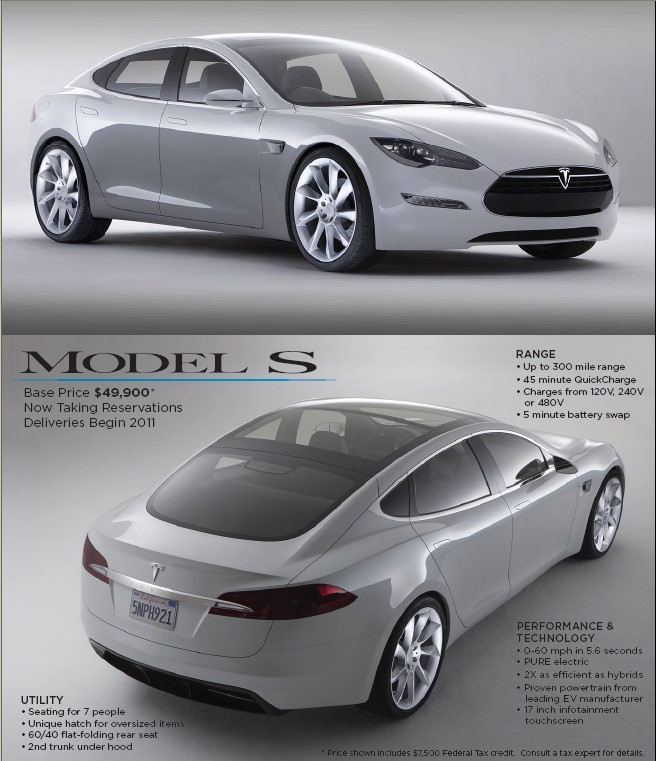

In addition to the Roadster, Tesla has plans to produce the Model S, an all-electric, 5-door sedan that can carry up to seven people as far as 482 km on a single charge. It was unveiled in March and production is set to begin in late 2011.

The sticker price for the Model S is expected to be $49,900 after a $7,500 federal rebate for buying an electric vehicle. Toronto Star