Flybrid mechanical KERS explained

|

| Flybrid mechanical KERS |

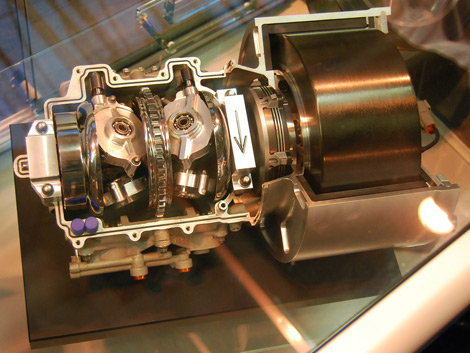

The Flybrid Kinetic Energy Recovery System (KERS) is a very small and light device that meets the FIA regulations for the 2009 season.

The key system features are:

- A flywheel made of steel and carbon fiber which rotates at over 60,000 RPM inside an evacuated chamber

- The flywheel casing features containment to avoid the escape of any debris in the unlikely event of a flywheel failure

- The flywheel is connected to the transmission of the car on the output side of the gearbox via several fixed ratios, a clutch and the CVT

- 60 kW power transmission in either storage or recovery

- 400 kJ of usable storage (after accounting for internal losses)

- A total system weight of 24 kg

- A total packaging volume of 13 liters

The layout of the device is tailored exactly to meet the customer's requirement resulting in a truly bespoke solution that fits within the tight packaging constraints of a F1 car.

Formula One System Diagram

Managing partner Jon Hilton explains:

"This is our demonstrator device for a Formula 1 KERS so the layout of it is correct. The output from middle gear to the car is adapted for every individual car so this is the core bit that would be fitted to any car.

"Drive comes into the device’s continuously variable transmission which provides a seamlessly changing ratio between the inputs and the flywheel. Control pistons manage the ratio within the CVT. It contains a clutch, an epicyclic gearbox and a flywheel. The flywheel spins much faster than the input drive – it’s a 5:1 ratio. Controlling the position of the levers manages the torque transfer within the CVT, and therefore how much energy is stored or released.

"The energy is stored in the flywheel which spins at 64,000 rpm. We’ve done a huge amount of work on safety, it was our number one concern when we started. We’ve done a lot of testing and the device is completely safe. We’ve applied for patent protections, and some of those are published now, on safety and containment. This device has an outer containment structure made of carbon fiber which is extraordinarily strong. It can contain pressures of up to 1,150 bar, so it’s enormously strong. If something were to break, it would be contained, for definite.

"It’s our view that changing the states of the energy – from mechanical at the wheel, to electric, to chemical at the battery, and back again, is a very inefficient route. The energy efficiency in a petrol-electric hybrid is about 37%, where ours is about 60%.

"The electric systems is what you would find in a Toyota Prius or Honda Civic Hybrid. Those systems are less powerful – the Prius’s is 23kW, this is 60kW. Performance of the devices in F1 is limited to 60kw, but this one is capable of 100kW, we restrict it to meet the rules, but it is much more powerful than the regulations allow. We are expecting them to increase the limit in the future and we’re ready and waiting for it.

It weighs 25kg in total including all the control hydraulics, the fluid that’s in it, electronics, everything. We looked at two different locations for installing it in an F1 car: one effectively sat on top of the gearbox, the other in front of the engine at the bottom of the fuel cell. There’s advantages and disadvantages to either place."