Renault previews their 2015 F1 plans

|

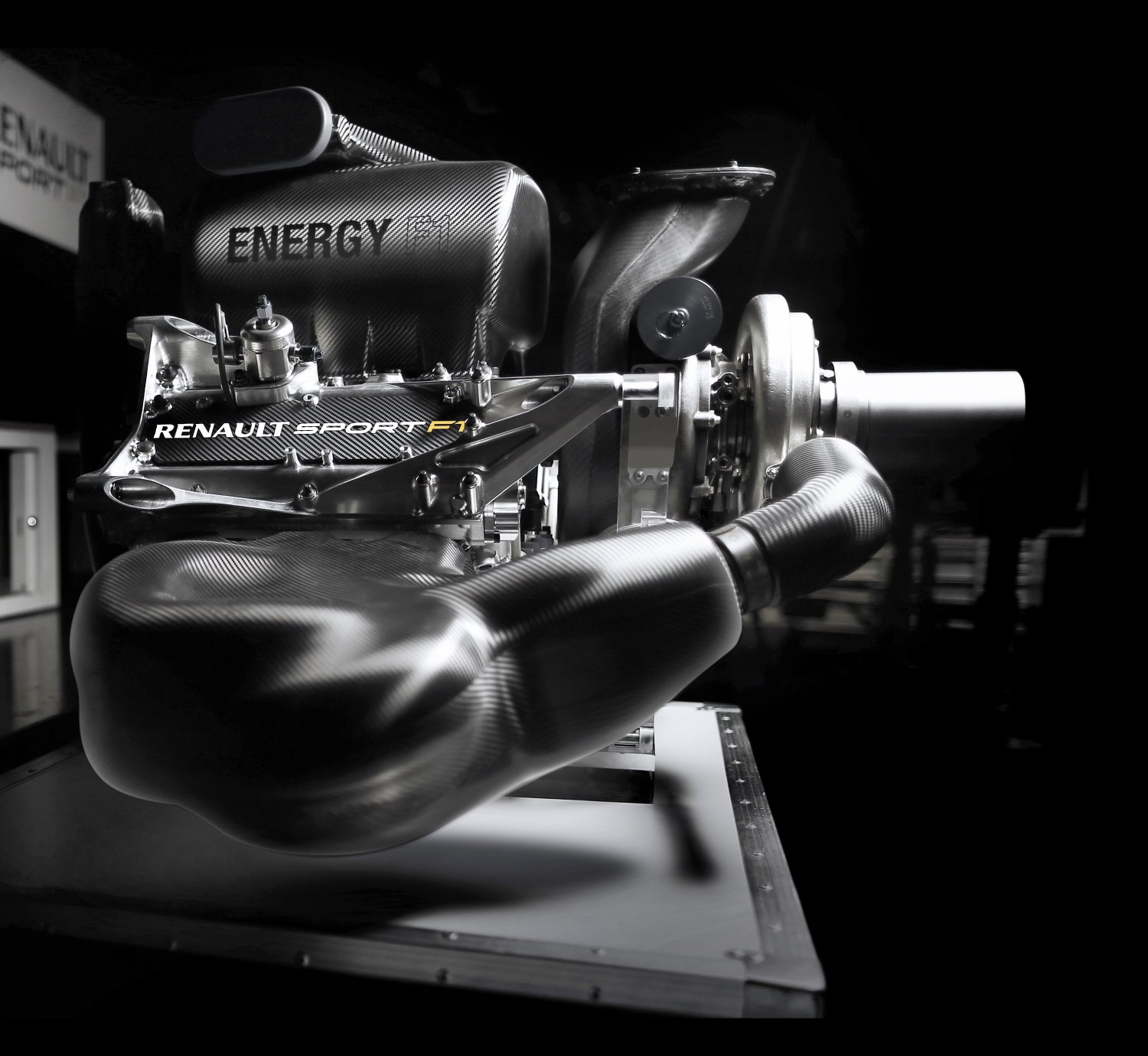

| 2015 Renault F1 Power Unit |

Renault enters the 2015 season with two objectives: to deliver competitive power units that run reliably and improves on its 2014 performance. After a tough season last year, the French manufacturer has taken a back to basics approach to achieving these aims, with a structural reorganization of its Viry-Chatillon headquarters the cornerstone.

'F1 constantly moves forward at a very fast rate. The sport evolves, technology evolves and the competition never sleeps so Viry needs to evolve at the same rate,' Managing Director Cyril Abiteboul explains. 'Viry needed a refresh. We did not suffer from a lack of resources or finances in 2014, it was simply that the resources were not joined up in time or used to their optimum.

'In the short gap between seasons we have therefore taken a number of steps forward. First and foremost we have implemented a new organizational structure. There is a numerous of changes in this new structure. I'll underline three of them to indicate where the focus will be in 2015.

'This new structure will emphasize the need for perpetual change and adaptation within Renault Sport F1. This will be achieved through two new streams led by Rob White and Jean-Paul Gousset. As Chief Technical Officer, Rob will use his in-depth knowledge of Renault Sport F1 to set the strategy and road map for the acquisition, development and utilization of technical skills within the company. Naturally this will always be with a close eye on our F1 project.

'In parallel, F1 performance is driven by human performance. Jean-Paul, who was previously head of production, is now appointed as Organization Performance Officer, and becomes responsible for organizational matters, procedures and protocols, from the small details to the large changes that together create and harness the racing spirit we want to see in Viry-Chatillon.

'Another substantial change is the creation of the Development Department, headed by Naoki Tokunaga. In addition to overseeing the Engineering Department, which is still managed by Jean-Philippe Mercier, Naoki will be directly responsible for Performance and Reliability Groups. These two groups are tasked with clear responsibilities as their name suggests, and allow us to get closer to the organizational model of F1 teams nowadays. This should build natural bridges and synergies with our customers.

[adinserter name="GOOGLE AD"]'The last noticeable change is that Remi Taffin will now oversee all track and factory operations, including assembly and dynos, in addition to continuing to look after the track operations. Regrouping all operations under one person aims to bring the excellent spirit of the track to the factory, simplifies our lines of communications, allows us to simplifies our lines of communications, allowing us to respond to changes or needs more quickly and ensure overall quality control and cost efficiency towards our internal and external customers.

'It is still very early to see the direct effects but all the changes are made for long term gain. We should start to see the full impact in development by the mid-season with greater flexibility, dynamism and efficiency across all our operations.'

Although the competition will again be tough, Renault hopes to deliver upwards of the three victories secured last season. 'We knew what we had to do over the winter and we know what we have achieved,' Cyril finishes. 'We believe we have made a very big step in performance and will be more reliable. We do not know where the others will be: we may not have erased all the gaps, but we are confident that we have gone a long way to making up the deficit of last season. Our objective is to close the gap as much as possible and give Red Bull Racing and Scuderia Toro Rosso a more competitive car on most circuits, independently of their characteristics and sensitivities.'

UPGRADING THE RENAULT ENERGY F1

2015 may be the second year of competitive use for the revolutionary power units, but they still remain a huge challenge for engine manufacturers. 'Year two of a new engine is always difficult,' Renault Chief Technical Officer Rob White explains. 'The 2015 power unit project was started six months before the 2014 units took to the track, ie. before we had any significant experience of the technology. Then we also needed to consider the issues arising during the season. It creates a need to be both forward thinking and reactive.

'Splitting resources between projects is therefore a delicate balancing act, in the short, mid and long term. While certain decisions can be taken upstream, a number of design decisions were taken quite late in the day, in order to benefit from the experience of the 2014 power unit. The result is a power unit that is very different to its predecessor.'

RINGING THE CHANGES

'We have made some fundamental changes to gain performance and reliability. We have upgraded every system and subsystem, with items that will give the most performance prioritized. The principal changes involve the internal combustion engine, turbocharger and battery. The ICE will have a new combustion chamber, exhaust system concept and variable trumpets, as permitted by the 2015 regulations. The compressor is more efficient, while the energy recovery systems are able to deal with more severe usage.

'The 2014 unit was already well placed in its centre of gravity, however we have tidied up the packaging to give greater ease of integration into the chassis. Additionally many systems and functions have been rationalized and simplified to further ease the task. In short, there are very few carry over pieces between the 2014 and 2015 power units.'

All the performance changes have been carried out under the 'token' system. The power unit is divided into sections and subassemblies, with a value allocated to each. The value is indicated by a number of tokens, with a total of 66 tokens per power unit. For the 2015 season, an engine manufacturer is permitted to select 32 tokens, or 48% of the engine.

IMPROVING RELIABILITY

With just four units per year now permitted, one fewer than in 2014, the required durability is increased and reliability is even more critical this season. Renault has taken measures to improve reliability for 2015. 'Admittedly last year our record was not the best we could have hoped for,' admits Director of Operations, Remi Taffin. 'But we worked very hard and made real improvements on reliability in the second part of the year.

'In fact we already had 2015 in mind last year as we ran all the parts to the life expected this season. That is, instead of running for the distance demanded by a five-per-year cycle, we tested them based on a four-per-year cycle, or 20% more than required.

'Having just four units to play with this year certainly gives us less flexibility,' he continues, 'And when a part has an issue it will be a lot more difficult to use again. However we feel prepared knowing that the parts have been running to the lifecycle needed for some time with very few issues.'

The aim this year is clear, but modest, as Rob ventures: 'First and foremost we need to run reliably, be quick and closer to front. We have made a significant step forward relative from 2014 and, although it is hard to quantify where we will be relative to the competition, what we can say is that we are on course to achieve our own performance objectives.'

RENAULT ENERGY F1-2015 POWER UNIT

|

|

The radical power units feature a turbocharged internal combustion engine coupled to potent energy recovery systems. They are hailed as the most sophisticated power plants ever seen on track. The V6 engine and its electrical motors is powerful, yet fuel efficient, capable of producing 850 horsepower using just 100kg of fuel per race.

KEY ELEMENTS

– 1.6l turbocharged V6 internal combustion engine

– Direct injection

– Max engine speed of 15,000rpm

– Potent Energy Recovery Systems incorporating two motor generator units – the MGU-H, recovering energy from the exhaust and the MGU-K recovering energy from braking

– Electrical energy recovered stored in a battery

– Combined maximum power output of 850bhp

– Double restriction on fuel consumption: fuel quantity for the race limited to 100 kg with fuel flow rate limited to 100 kg/hr max

– 4 Power Units permitted per driver per year

RENAULT ENERGY F1 DECODED

INTERNAL COMBUSTION V6 ENGINE

V6 is shorthand for an internal combustion engine with its cylinders arranged in two banks of 3 cylinders arranged in a 'V' configuration over a common crankshaft. The Renault Energy F1 V6 has a displacement of 1.6 liters and will make around 600bhp, or more than 3 times the power of a Clio RS.

DIRECT FUEL INJECTION

All Power Units must have direct fuel injection (DI), where fuel is sprayed directly into the combustion chamber rather than into the inlet port upstream of the inlet valves. The fuel-air mixture is formed within the cylinder, so great precision is required in metering and directing the fuel from the injector nozzle. This is a key sub-system at the heart of the fuel efficiency and power delivery of the power unit.

TURBOCHARGER

A turbocharger uses exhaust gas energy to increase the density of the engine intake air and therefore produce more power. Similar to the principle employed on roadcars, the turbocharger allows a smaller engine to make much more power than its size would normally permit. The exhaust energy is converted to mechanical shaft power by an exhaust turbine. The mechanical power from the turbine is then used to drive the compressor, and also the MGU-H (see below).

WASTEGATE

On conventional turbo engines, a wastegate is used in association with a turbocharger to control the high rotation speeds of the system. It is a control device that allows excess exhaust gas to by-pass the turbine and match the power produced by the turbine to that needed by the compressor to supply the air required by the engine. On the Renault Energy F1 power unit, the turbo rotation speed is primarily controlled by the MGU-H (see below) however a wastegate is needed to keep full control in any circumstance (quick transient or MGU-H deactivation).

MGU-K

The MGU-K is connected to the crankshaft of the internal combustion engine. Under braking, the MGU-K operates as a generator, recovering some of the kinetic energy dissipated during braking. It converts this into electricity that can be deployed throughout the lap (limited to 120 kW or 160bhp by the rules). Under acceleration, the MGU-K is powered from the Energy Store and/or from the MGU-H and acts as a motor to propel the car.

MGU-H

The MGU-H is connected to the turbocharger. Acting as a generator, it absorbs power from the turbine shaft to convert heat energy from the exhaust gases. The electrical energy can be either directed to the MGU-K or to the battery for storage for later use. The MGU-H is also used to control the speed of the turbocharger to match the air requirement of the engine (eg. to slow it down in place of a wastegate or to accelerate it to compensate for turbo lag.)

BATTERY (OR ENERGY STORE)

Heat and Kinetic Energy recovered can be consumed immediately if required, or used to charge the Energy Store, or battery. The stored energy can be used to propel the car with the MGU-K or to accelerate the turbocharger with the MGU-H. Compared to 2013 KERS, the ERS of the 2015 power unit will have twice the power (120 kW vs. 60 kW) and the energy contributing to performance is ten times greater.

INTERCOOLER

The intercooler is used to cool the engine intake air after it has been compressed by the turbocharger.

RENAULT ENERGY F1-2015 POWER UNIT TECHNICAL SPECIFICATION

ENGINE ENERGY F1-2015

Displacement 1.6L V6

Number of cylinders 6

Rev limit 15,000rpm

Pressure charging Single turbocharger, unlimited boost pressure (typical maximum 3.5 bar abs due to fuel flow limit)

Fuel flow limit 100 kg/h

Permitted Fuel quantity per race 100 kg

Configuration 90° V6

Bore 80mm

Stroke 53mm

Crank height 90mm

Number of valves 4 per cylinder, 24

Exhausts Single exhaust outlet, from turbine on car centre line

Fuel Direct fuel injection

ENERGY RECOVERY SYSTEMS

MGU-K rpm Max 50,000rpm

MGU-K power Max 120kW

Energy recovered by MGU-K Max 2MJ/lap

Energy released by MGU-K Max 4 MJ/lap

MGU-H rpm >100,000rpm

Energy recovered by MGU-H Unlimited (> 2MJ/lap)

GENERAL

Weight Min 145 kg

Number of Power Units permitted per driver per year 4

Total horsepower Approx 850hp

INTERVIEW WITH CYRIL ABITEBOUL

|

| Abiteboul |

It's been a short winter break this year, but Renault Sport F1 has nevertheless made a lot of progress. Can you explain the areas where you have moved forward?

In the short gap between seasons we have taken a number of steps forward. First and foremost we have implemented a new organizational structure.

Our new structure will emphasize the need for perpetual change and adaptation within Renault Sport F1. This will be achieved through two new functions. As Chief Technical Officer, Rob White will use his in-depth knowledge of Renault Sport F1 to set the road map and a strategy for the acquisition, development and utilization of technical skills within the company, always with a close eye on our F1 project.

As everyone knows, F1 performance is driven by human performance so we have created another stream in parallel to manage all organizational matters, procedures and protocols. Jean-Paul Gousset, who was previously head of production, is now responsible for this area, from the small details to the large changes that together create the racing spirit we want to see in Viry-ChÃÆ'¢tillon.

Another substantial change is the creation of the Development Department, headed by Naoki Tokunaga. In addition to overseeing the Engineering Department, which is still managed by Jean-Philippe Mercier, Naoki will be directly responsible for Performance and Reliability Groups.

With all our operations streamlined, there will be a seamless link between factory and track, giving further leverages for managing the workforce and activity workloads, plus will create career paths. Remi Taffin will oversee all track and factory operations, including assembly and dynos, in addition to his previous role as head of track operations. Regrouping everything under one person simplifies our lines of communications, allowing us to respond to changes or needs more quickly and ensure overall quality control and cost efficiency.

What advantages do you hope to gain from this new structure?

It is still very early to see the direct effects but all the changes are made for long term gain. We should start to see the full impact in development by the mid-season with greater flexibility, dynamism and efficiency across all our operations.

Are the changes linked directly to 2014 performance?

[adinserter name="GOOGLE AD"]Not specifically. F1 constantly moves forward at a very fast rate. The sport evolves, technology evolves and the competition never sleeps so Viry needs to evolve at the same rate. Viry needed a refresh. We did not suffer from a lack of resources or finances in 2014, it was simply that the resources were not joined up in time or used to their optimum. We are not in any way pointing fingers at individuals, these changes are simply to improve the collective.

How will the changes benefit Renault's partner teams?

The performance and reliability groups are tasked with clear responsibilities and allow us to get closer to the model of F1 teams nowadays, which should build natural bridges and synergies with our customers. Replicating the structure of a team in our own organization means we will fit more easily into the team culture and create more natural communications. With fewer 'hurdles' to jump we should be more creative, freer to execute decisions and implement actions as a result.

Will personnel from the larger Renault Group continue to be seconded to Renault Sport F1?

Yes, more than ever. We need to create strong and genuine links between road cars and competitive sport in both directions. Renault needs to help our F1 division and F1 needs to help Renault. The personnel we have on board bring new knowledge to us and, in turn, take some lessons of F1 back to road car development when they return. At present there are Renault personnel in several departments that will bring gains to road car areas, for example, fuel efficiency and electrical systems.

What are Renault Sport F1's aims for 2015?

We knew what we had to do over the winter and we know what we have achieved. We believe we have made a very big step in performance and will be more reliable. We do not know where the others will be: we may not have erased all the gaps, but we are confident that we have gone a long way to making up the deficit of last season. Our objective is to close the gap as much as possible and give Red Bull Racing and Scuderia Toro Rosso a more competitive car on most circuits, independently of their characteristics and sensitivities.

INTERVIEW WITH ROB WHITE

|

| Rob White |

Chief Technical Officer

What are the challenges going into the second year of the power units?

Year two of a new engine is always difficult. The 2015 power unit project was started six months before the 2014 units took to the track, ie. before we had any significant experience of the technology. Then we also need to consider the issues arising during the season. It creates a need to be both forward thinking and reactive.

Splitting resources between projects is a delicate balancing act, in the short, mid and long term. While certain decisions can be taken upstream, a number of design decisions were taken quite late in the day, in order to benefit from the experience of the 2014 power unit. The result is a power unit that is very different to its predecessor.

What are the principal changes to the Renault Energy F1 for the 2015 season?

We have made some fundamental changes to gain performance and reliability. We have upgraded every system and subsystem, with items that will give the most performance prioritized. The principal changes involve the internal combustion engine, turbocharger and battery. The ICE will have a new combustion chamber, exhaust system concept and variable trumpets, as permitted by the 2015 regulations. The compressor is more efficient, while the energy recovery systems are able to deal with more severe usage.

The 2014 unit was already well placed in its centre of gravity, however we have tidied up the packaging to give greater ease of integration into the chassis. Additionally many systems and functions have been rationalized and simplified to further ease the task. In short, there are very few carry over pieces between the 2014 and 2015 power units.

This year the power unit is broken down into 'tokens'. How does this system work?

This year there are regulatory limits to do with 'token' spend that determine the number of changes we can make. The power unit is divided into sections and then subassemblies associated to it. The total number of tokens within the power unit is equal to 66. Five out of the 66 tokens are not available for change as they are frozen. An engine manufacturer is able to select 32 token areas, or 48% of the engine, which he would like to change. As the technology gets more mature next year and beyond there will be fewer and fewer tokens available to spend. Clearly the juggling act we need to perform is which areas of the power unit are the most worthwhile to attack for performance reasons.

How has Renault decided to allocate its tokens?

We have used the majority of the tokens for the first race and our use of tokens during the course of the season will be relatively modest. It then becomes a matter of strategy about when you introduce the remaining tokens; whether to introduce at the start of the season when the technology is relatively immature but could give greater relative performance, or later in the season when the part has had more testing miles but the impact on performance will be potentially less. We can still make changes for reliability under the sporting regulations. We have therefore prioritized token spend to make as much headway as possible with performance.

What are your aims for 2015?

First and foremost we need to run reliably, be quick and closer to front. Our honest expectation is that we will make a decent improvement but it is difficult to quantify the gain relative to our competitors who will also progress. What we can say is that we are on course to make a significant performance step and resolve the principal reliability weaknesses by the time we get to the first race.

INTERVIEW WITH REMI TAFFIN

|

| Remi Taffin |

Are there any particular areas of the power unit you have worked on to give performance?

We have made lots of changes to the power unit across all areas from last year. We won't go into specifics about each and every part we have changed, but we will arrive in Melbourne with a very different engine to last year. This year we can cash in up to 32 tokens over the season and we plan to use a great deal for Australia, with some saved for use during the year to give flexibility.

Reliability is also a big topic in 2015, with only four power units permitted this year. What steps have you taken to improve reliability?

Admittedly last year our reliability record was not the best we could have hoped for but we worked very hard in this area and made some real improvements on reliability in the second part of the year. In fact we already had 2015 in mind last year as we ran all parts to the life expected this season. That is, instead of running for the distance demanded by a five-per-year cycle, we tested them based on a four-per-year cycle, or 20% more than required. Even though we pushed the parts harder than they needed to go last year, it gave us the starting point for 2015.

How has the reduction in units changed your approach?

Having just four units to play with this year certainly gives us less flexibility and when a part has an issue it will be a lot more difficult to use again. However we feel prepared knowing that the parts have been running to the lifecycle needed for some time with few issues.