Touring the Mercedes-Benz Assembly Plant in Germany

Most race fans associate Mercedes Benz with the successful Mercedes- AMG Petronas Formula One team, which Lewis Hamilton, the seven-time champion, and George Russell currently drive for. The team has eight Constructors’ championships and nine driver championships, the most recent ones won by Hamilton seven years in a row, from 2014-2020.

I recently was able to take a tour of the Mercedes Benz assembly plant in Rastatt, Germany, the lead plant in the compact vehicle global products network. It was impressive to see the sprawling 147-hectare site, which has multiple buildings for various operations and also has buildings onsite for several vendors which supply parts to the cars during the manufacturing process. The Type A, EQA, and GLA are made at this plant.

Mercedes-Benz Showroom in Rastatt, Germany Photo by Lucille Dust/AR1

Before the tour, we viewed a six-minute video explaining the company’s motto and the high standards that they require in all their cars. The motto is “We do not just build a car, we want to build the best and most intelligent car”.

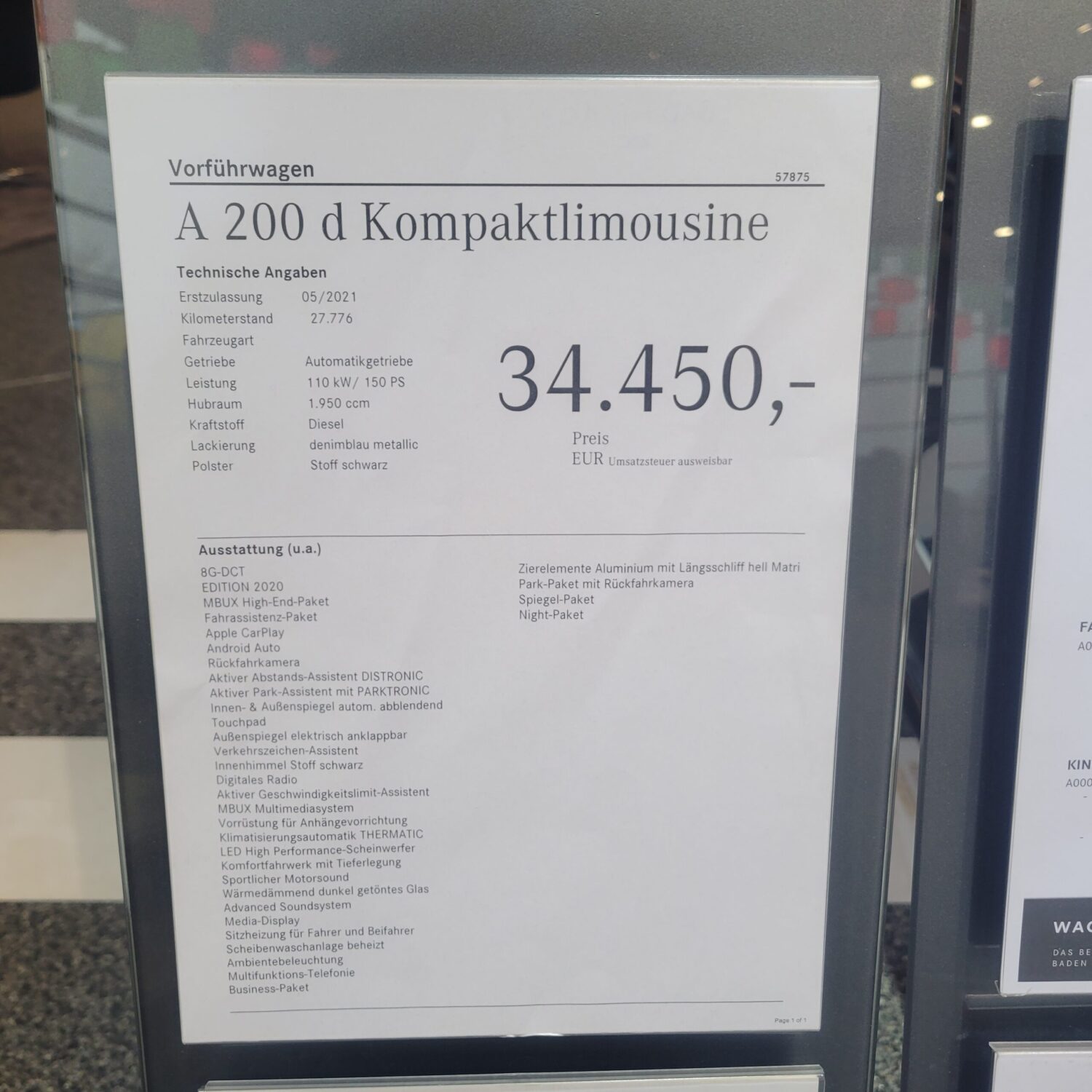

The thing I was most surprised at was that every car is produced by customer order. And if you are in Germany, you can pick up your car in this showroom at the assembly plant when it is completed. Customer pickup is 20% of the cars produced in this plant. Of the 300,000 cars produced in a year, only two were identical.

Typically, the timeline is six months from your order to the pickup of the finished product. Due to the supply shortages, the making of the luxury car is taking 12 months to complete. This also reduced the shifts worked from three to two during this time, which explains the extended completion time. This plant produces 800 cars a day, down from 1,300 before the shortages, in a five-day workweek.

Now being an American, I had to ask how the cars were produced for the consumers in the United States. The knowledgeable guide answered that the dealerships pick out the options they want on their cars and then place the orders.

No pictures are allowed to be taken in the plant due to the company’s policy of not having their employees photographed.

The plant has a typical automaker assembly line for production with 6,500 people employed at this location. Only 20 percent of the line has robots doing certain steps that they can maneuver better than humans, like installing the custom dashboards, with just two screws, and the windshields.

Each employee on the line has 80 seconds to complete their task for each car. There are teams of 40 people, and they rotate the tasks between the team every two hours.

All the paint on the body of the car is done by robots. The process happens in another part of the plant and then the parts of the cars are transferred to the assembly line by a rail line in the plant. A visitor cannot see the paint shop because of the 100 percent clean-room conditions.

Our guide stopped and raved as we watched the “wedding” of the power train to the body shell. 48 screws are used to attach the two and are installed in the 80-second time frame. This step happens about halfway through the assembly.

There are 4,000 welding points on each car and every single one has to be perfect. Many robots have the task of doing this intricate function to insure that perfection is achieved.

Each new car is inspected for 30 minutes once the car is finished and comes off the assembly line. It is driven outside and checked for Mercedes-Benz benchmark levels of quality.

More electric-powered cars will be produced in the coming years at this plant. There was some talk that in Germany the situation for charging the vehicles and using home chargers are currently not as practical as the automakers would like to think. Some progress would need to take place before an electric automobile would be in every home.

This was very impressive to see how the German manufacturer makes the top-of-the-line luxury automobiles and how high the standards are for this company.

Lucille Dust reporting for AutoRacing1.com