Argonne’s lithium-ion battery technology to be commercialized by BASF

|

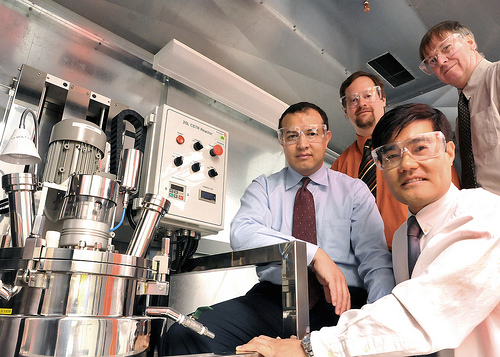

| Argonne National Laboratory battery researchers (from left) Khalil Amine, Chris Johnson, Sun-Ho Kang and Mike Thackeray flank a continuously-stirred tank reactor used to produce scaled-up quantities of cathode materials for lithium-ion batteries. Argonne’s lithium-ion battery technology will be commercialized by chemical company BASF under a licensing agreement announced on June 3 |

The U.S. Department of Energy's (DOE) Argonne National Laboratory and BASF, the world's largest chemical company, have signed a world-wide licensing agreement to mass produce and market Argonne's patented composite cathode materials to manufacturers of advanced lithium-ion batteries. The patented cathode materials licensed to BASF are part of a large and diverse suite of lithium-ion battery inventions and patents developed at Argonne with funding from DOE's Vehicle Technologies Program.

BASF will conduct further lithium-ion battery material application development in its current Beachwood, Ohio facility. Contingent upon winning a DOE grant under Recovery Act – Electric Drive Vehicle Battery and Component Manufacturing Initiative (DE-FOA-0000026), BASF plans to build one of North America's largest cathode material production facilities in Elyria, Ohio.

The patented cathode materials licensed to BASF are part of a large and diverse suite of lithium-ion battery inventions and patents developed at Argonne with funding from DOE's Vehicle Technologies Program. The further development and commercialization of the cathode materials will result in advanced batteries that are higher-performing, longer-lasting and safer when compared to the existing technology that has dominated the market for nearly two decades.

“BASF is excited to begin this partnership with Argonne National Laboratory as we look to advance the lithium-ion battery market in North America," said Joseph Breunig, BASF Corporation President of Market and Business Development. “The aim of our application development team in Beachwood, Ohio, along with our funding proposal to DOE for a world class facility in Elyria, Ohio is to make lithium-ion battery use realistic, affordable and widely available. Partnerships like this are exactly the type of public-private investment commitment that will create a more sustainable environment, help move the economy forward and create new jobs."

"This licensing agreement has the potential to put the United States several steps closer to reaching President Obama's goal of having one million plug-in hybrid electric vehicles on the road by 2015," said Argonne Director Eric Isaacs. "The transfer of Argonne-developed battery technology to BASF provides a stellar example of why DOE invests taxpayer dollars into scientific research and development. When federally funded R&D is commercialized, it enhances our economic competitiveness, energy security and quality of life through innovations in science and technology."

When completed, the proposed BASF facility in Elyria, Ohio, is expected to be the largest cathode material production facility in North America. The cathode material licensed from DOE has been shown to be a material of choice among the largest North American and Asian cell manufacturers that are actively engaged in providing lithium-ion battery solutions to the automotive and other commercial marketplaces. The impact of such a facility is anticipated to be significant as the facility construction and staffing will have a positive economic impact for Ohio and will attract further businesses to North America.

“The strong relationship between BASF and Argonne National Laboratory will accelerate our efforts to commercialize lithium-ion battery materials," said Thomas Weber, Managing Director, BASF Future Business. “ It will strengthen our competencies, speed up our efforts and show our continued commitment within BASF's Energy Management cluster. Together we are taking a major step forward in cultivating economically viable opportunities to provide an already proven source of clean energy in North America."

“With this new license and proposed production plant, BASF will invest substantial financial resources in Ohio to bring good-paying, clean-energy jobs to our state," said U.S. Rep. Betty Sutton (D-OH). “The company's subsequent innovation will spur critically needed jobs in Ohio, where the unemployment rate in April was 10.2 percent. Further, the development of next-generation lithium-ion batteries is essential for our country to compete in today's global economy. Through this development, Ohio can be especially influential in the clean-energy jobs of the future."

“This is one example of how we will make Ohio the Silicon Valley of clean-energy manufacturing," said U.S. Sen. Sherrod Brown (D-OH). “Lithium-ion batteries will be used in electric cars, which represent the future of the auto industry. The agreement with Argonne and the proposed building of the factory will enable Ohioans working in BASF facilities in Beachwood and Elyria to research, develop and manufacture lithium-ion battery components. This will help bring new economic activity and a cleaner future to our state."

Argonne's composite cathode material employs a unique combination of lithium- and manganese-rich mixed-metal oxides in a revolutionary materials-design approach to extend the operating time between charges, increase the calendar life and improve the inherent safety of lithium-ion cells. Moreover, the enhanced stability of the composite material permits battery systems to charge at higher voltages, which leads to a substantially higher energy storage capacity than currently available materials through both the higher voltage and higher capacity per unit weight of active material. BASF intends to commercialize these cathode materials for transportation and other applications.

"This licensing agreement has tremendous potential," said Stephen Ban, Director of Argonne's Office of Technology Transfer. "As the world's largest chemical company, BASF's ability to make these advanced materials widely available is beyond compare and will be a significant factor in aiding the penetration of the next generation of lithium-ion batteries into the U.S. marketplace through production facilities planned for the Midwest and elsewhere."