Formula E partners with battery recycling company

|

| The Williams Advanced Engineering battery powered Formula E cars the equivalent distance to the Moon and back – 240,000 km over 45 races |

The ABB FIA Formula E Championship has today announced a new partnership with Umicore – the Belgian materials technology and recycling group – as official battery recycling supplier, to recycle the lithium-ion battery units and cells used during the first two seasons of the electric street racing series.

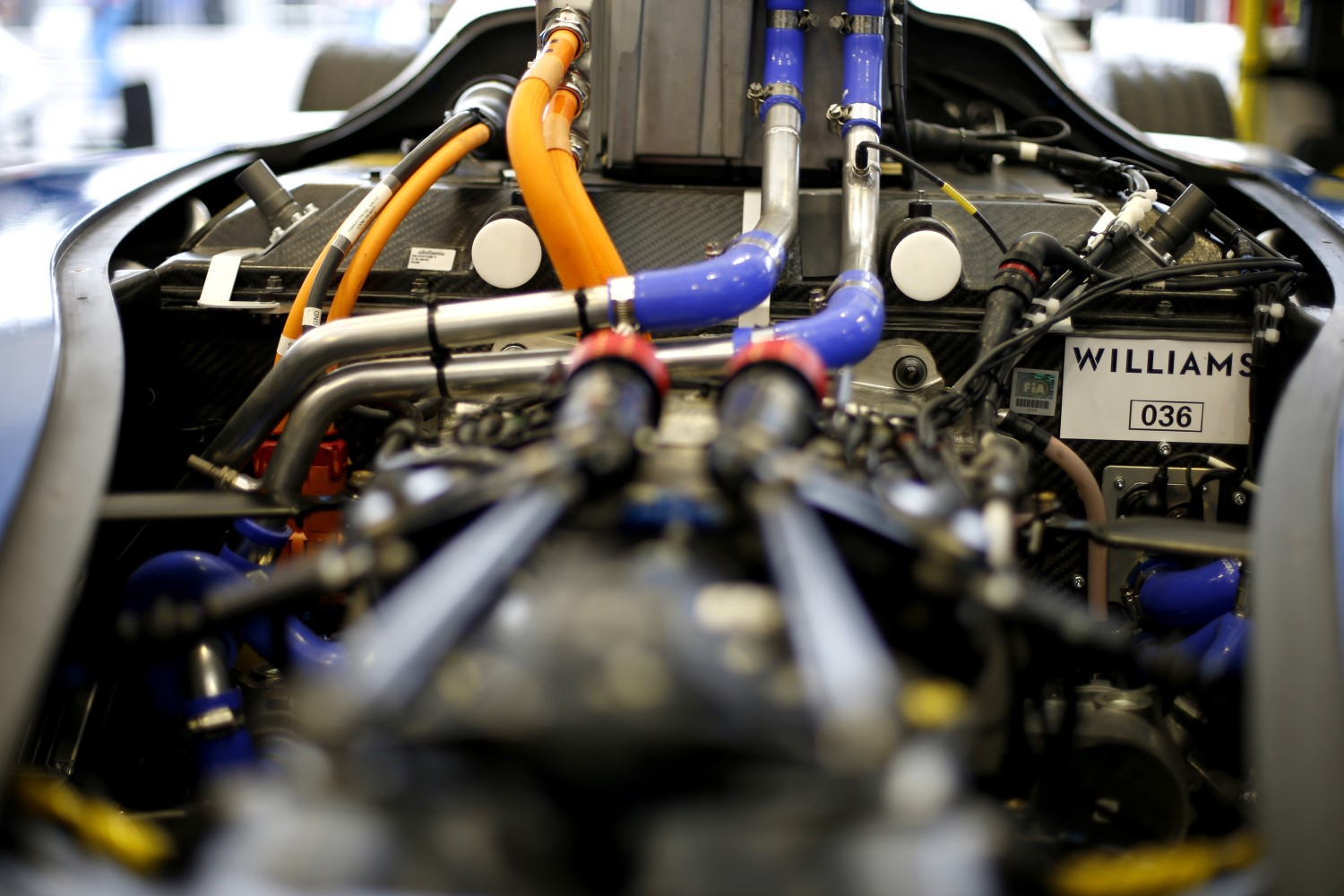

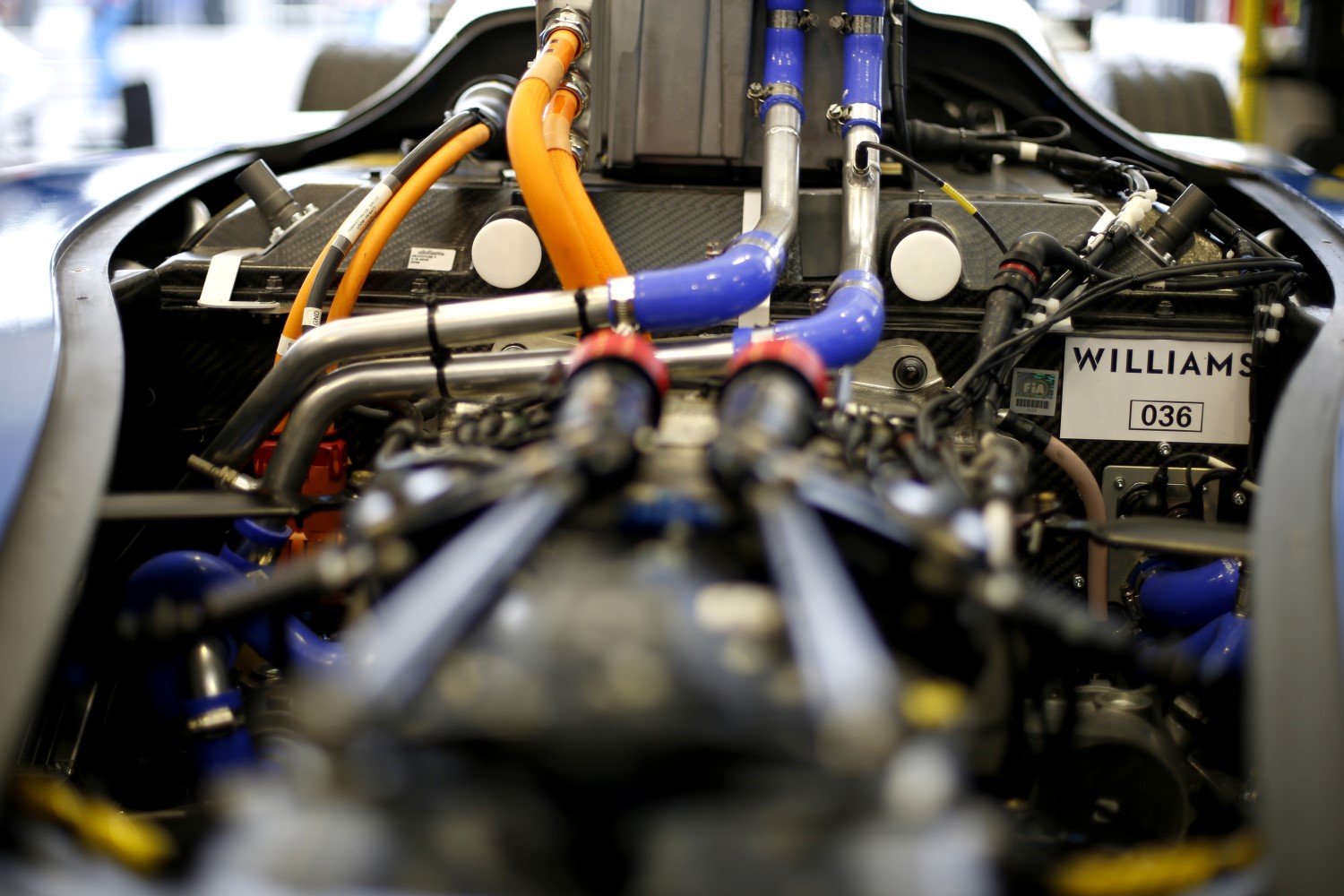

The Formula E batteries from season one and two, created by Williams Advanced Engineering, have been collected and are in the process of being recycled by Umicore. The process comprises of sorting, dismantling and recycling with valuable metals being carefully recovered using proprietary and unique smelting technology – followed by hydrometallurgical treatment.

The metals in the battery are infinitely recyclable without losing their properties. After collection, the batteries are taken apart using methods to ensure the environment isn’t exposed to hazardous compounds. Recycling includes the recovery of the metals and transformation into metal alloys that will be used again in new rechargeable batteries, or other products.

Umicore is one of only a few companies worldwide to offer a complete recycling journey. Its unique ‘closed loop’ approach for lithium-ion rechargeable batteries ensures there’s minimal waste or impact on the environment, which will be vital as the adoption of electric vehicles becomes more mainstream.

Umicore is a pioneer in providing customers in the rechargeable battery value chain with materials of a certified clean and ethical origin. The company has been ranked seventh in the 2019 top-100 of the world’s most sustainable companies published by Corporate Knights.

Alejandro Agag, Founder & CEO of Formula E, said: “This is an important moment for Formula E and I’m grateful to be partnering with Umicore on this initiative. Sustainability is at the core of both companies, and to be able to recycle our battery cells with a closed loop approach means we’re doing our utmost to limit the impact we have on the environment – while promoting a wider message of clean mobility."

Kurt Vandeputte, Senior Vice-President Rechargeable Battery Materials Umicore, said: “It’s an honor for Umicore to demonstrate our closed loop business approach for the lithium-ion batteries in Formula E. After introducing our battery materials expertise as technology partner with MAHINDRA RACING in the championship, we’re excited to now also offer our ‘closing the battery loop’ sustainable recycling solution for the end-of-life batteries of season one and two."

Paul McNamara, Technical Director of Williams Advanced Engineering, said: “Williams Advanced Engineering has long been leading the way on electrification of racing and sustainable transport, which can only be truly sustainable if the products involved are recyclable. The team at Williams Advanced Engineering takes great pride in its foundational role enabling the launch and development of Formula E across its first four seasons, with batteries that ran at better than 99.5 per cent race reliability. We congratulate Formula E on the unveiling of this initiative."